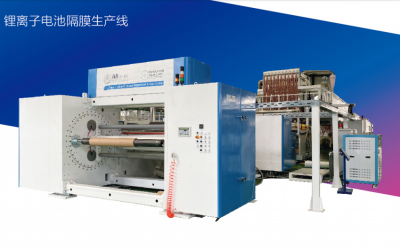

PP Multi-layer Co-extruded Cast Sheet Line

Features of Machine

Coextrusion by multiple extruders, with the advantages of less production process, low energy consumption and low cost.

The whole line is controlled by PLC and touch screen.

Characteristics of Product

The PP sheet is 0.18-2mm thickness, non-toxic, odorless, healthy, environmental, good appearance, high mechanical strength, good barrier, high and low temperature resistance, high transparency and good flexibility, available for silk screen printing, stamp mark, gold stamping. It meets with food testing standard and can be used for microwave oven.

Main Application of Product

It is mainly used for disposable meal box, fruit and vegetable tray, moon cake tray and other food trays, and also suitable for the packaging of high cold and frozen food, such as ice cream box, dumpling box, sweet dumpling box, etc.

Model (mm)

800

Screw Diameter (mm)

55/110/80

Ratio of Screw(L/D )

35:1

Width of Die (mm)

900

Width of Film (mm)

600-800

Thickness of Film (mm)

0.18-2

Structure of Film

A/B/B/C/C,A/B/C/A,A/C/B/C/A

Max Extrusion Capacity (kg/h)

400

Design Line Speed (m/min)

20

Total Installed Power (kw)

320

Overall Dimensions (m)

17×3×3.5

Weight (T)

20