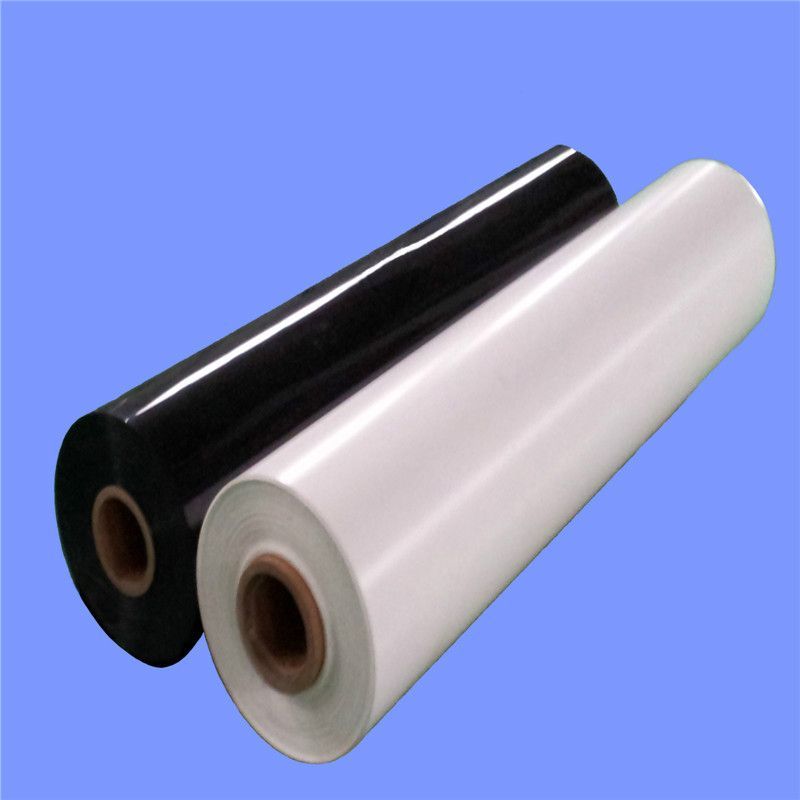

PVDF/ETFE Cast Film Line

With special extruder and die, this line is designed for producing PVDF film by cast extrusion technology. The film can be used for solar cell backsheet, PVDF permeable film for water treatment, PVDF protective film for outdoor building and other special functional PVDF film.

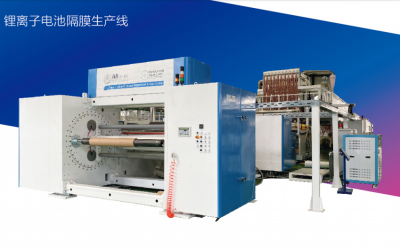

Features of Machine

1.The extruder made of special steel with high temperature resistance and corrosion resistance realizes the stable fluoroplastic extrusion.

2. Cooperating with colleges and universities, this line is specially designed the structure of screw and die for the specificity of fluorine material and realized the reasonable, industrialized and large-scale production of fluoroplastic film by corresponding special forming, winding etc process technology.

The whole machine is high configuration, practical and reasonable design, controlled by PLC

3.touch screen and interlocking control which are convenient and safe.

Characteristics of Products

1. The thickness of PVDF fluoroplastic film is 20-40um, width up to 2500mm, line speed 5-100m/min, other specific requirements can be customized at request.

2. ETFE film is an alternative material with super quality in the transparent architectural structures. Its unique self-cleaning surface makes it high anti-dirty and easy-washing. Usually, the main dirt on it can be cleaned by rain water.

3. ETFE film is anti-aging, corrosion resisting and long-life etc. Generally the usage life is between 25 and 35 years.

4.ETFE film is with light and high fireproofing grade. It will not drop when burning.

5.The light transmittance of ETFE film is very high, even more than 90%.

6.ETFE film is environmental-friendly and recyclable. It can be completely recycled and reused to produce other ETFE products.

Main Applications of Products

1. Currently, PVDF film is mainly used for solar cell backsheet: laminate fluoroplastic film at both sides of PET substrates to get three-layer structure, the outer layers are T film, the intermediate layer is P film, and EVA is used to stick T and P. T is polyvinyl fluoride (PVF) around 37um thickness, this layer is the main layer of solar cell encapsulation material for weather fastness, UV resistance, aging resistance and light tight; P is polyester film PET at 250um thickness for moisture barrier, electric insulation, size stability, easy processing and tearing resistance. The solar cell backsheet is used for protecting cell in photovoltaic assembly, with reliable insulation, water tightness and aging resistance. The PVDF film can replace polyvinyl fluoride (PVF) in TPT and can get three-layer structure (PVDF/PET/PVDF), the outer protective layer PVDF is resistant to environmental erosion, the intermediate layer PET has good insulation, the inner layer PVDF and EVA has good adhesive property.

2. The ETFE film is transparent with thickness less than 0.20mm. This film is usually made into air cushion in film structure. The earliest ETFE project is more than 20 years old, known as British Eden. The main stadium-natatorium of Beijing Olympics 2008 used this film as roofage. “Water Cube” is the largest film structure project in the world, its external structures adopted worldwide advanced ETFE film material with environmental protection and energy saving. ETFE film is used for not only building and agriculture, but also windproof glass film for automobile, anti-dirty internal and external packaging material, battery separator, bond container, conveying belt for food industry, solar receiver, circuit board for flexible printing, computer wire, medical packaging film and so on.

3. The ETFE film as curtain wall or roofage is newly developed in recent years, and has been applied widely to over 100 projects all over the world. The main stadium-natatorium of Beijing Olympics 2008 used this film as roofage and was made up of 3000 air bags, with areas up to 110,000 m2, the total usage of ETFE material is up to 200 tons. But up to now there is no company to process high quality and wide ETFE film in China. After Olympics 2008, its usage is increased

in multiple, which makes fluoroplastics into middle and high-end market.

The specific specification can be made according to customer's requirement.