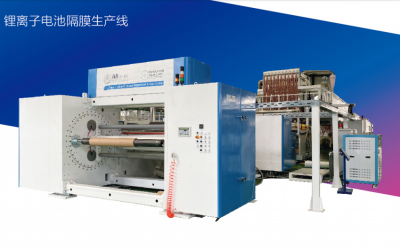

CPET/OPET Plastic Extrusion Cast Film Line

Features of Machine

Adopt single/double-screw extrusion structure to produce single/double or three-layer co-extrusion cast film.

With the specificity or modified features of PET material, adopt specially-designed extrusion processing technic to produce high quality or special orientation film by dehumidification drying----auto dosing----extrusion plasticization----T-die----forming unit----automatic thickness control system----preheating, stretching and molding unit----surface treatment unit----edge cutting and edge trim unit----fully auto winder unit, the film can be used for every field.

Characteristics of product

According to the special property of film in different fields, this film not only has excellent physical and mechanical properties but also has excellent optical property, good transparency, low haze, high gloss, good heat stability, low hot-shrinkage rate, flat, smooth and clean surface, good stripping, anti-aging etc. properties. And OPET film has high uniaxial tension strength and uniaxial orientation property which is for special fields. PET shrink film is a new type of packaging material due to easy recycling, non-toxic, tasteless, good mechanical properties, especially be up to the demand of environmental protection.

Main application of product

1. tinplate lamination film: laminating with tinplate for packing food and drink etc.

2.Electronic component packaging: can be made into antistatic packaging bag for packaging of shielded sensitive electronic components, circuit board, communication equipment and electronic products etc.

3. Pharmaceutical Packaging: mainly for tablet packaging.

4. chemical coating base film: In order to improve the surface property of PET film and promote printing flexibility and binding force of vacuum aluminum plating layer, this base film avoids the way of corona treatment to improve rapid reduction of film surface wet tension in hot and humid environment, promote printing flexibility, strengthen the binding fore with aluminum plating layer and increase the thickness of aluminum plating layer.

5. Hot shrink film: PET hot shrink film is a new type of hot shrink packaging material. In developed countries, PET film has replaced PVC hot shrink film as the ideal replacements due to the characteristics of easy recycling, non-toxic, tasteless, good mechanical properties and especially environmental protection.

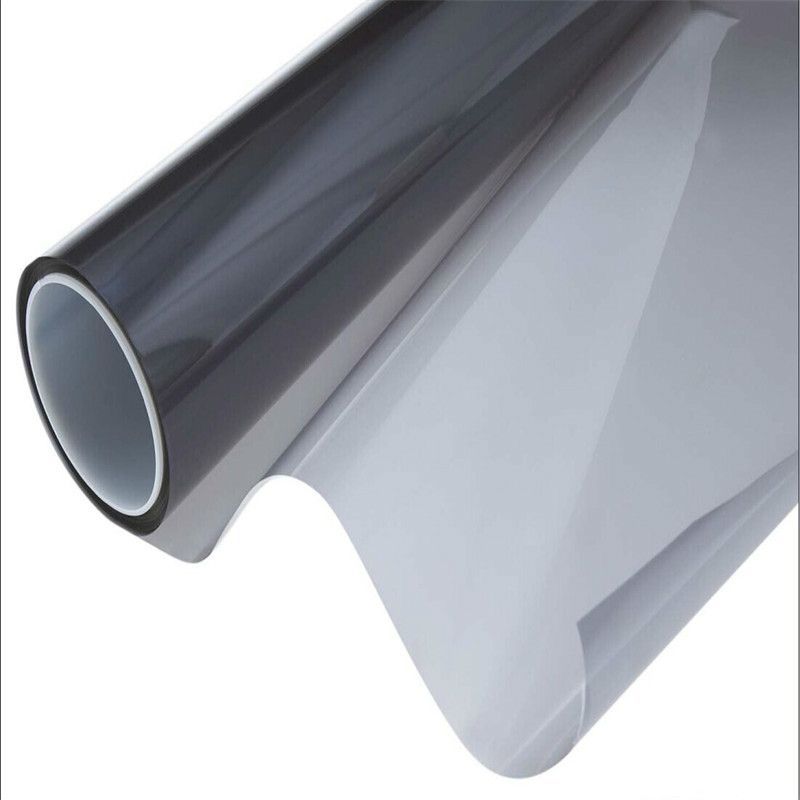

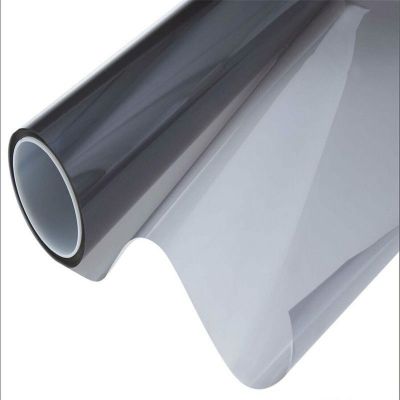

6. Solar film base film (glass film): it is a kind of multilayer polyester film posted to plate glass surface and high-tech energy-saving product which can control solar thermal radiation effectively and increase glass strength, belonging to a new type of energy-saving building materials. PET solar film can improve the property and strength of glass and make the glass have the functions of energy-saving, heat insulation, insulation, anti-explosion, anti UV, good appearance, shield privacy, safe etc., it is mainly used for doors and windows of car and building, partition, ceilings etc.

7. CPET film is also applied for low temperature radiant electrothermal film, motor and generator insulation, wire and cable insulation layer etc.

The specific specification can be made according to customer’s requirement.