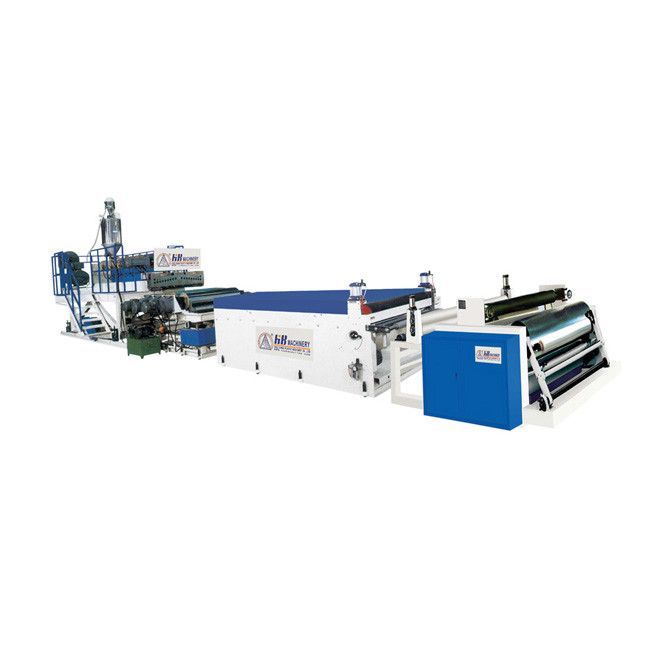

EVA/PU Three-dimensional Environmental Flexible Film/Sheet Line

This line is designed for producing EVA/PU environmental flexible film/sheet by advanced cast flexible film surface molding technology.

Features of Machine

1.High efficient plasticization screw and advanced back pressure device can eliminate the gem effectively.

2.It can produce different colors of products with transparent, three-dimensional, frosted and so on by advanced flexible calendaring and forming process.

3.Electrical control system adopts world-advanced servo technology with man-machine interface, convenient and accurate.

Characteristics of Product

1.No plasticizer and heavy metal, conforming to standards of America FDA, F963 and EU ROHS, compliance with current environmental new tide, a replacement of PVC and other materials.

2.EVA/PU adhesive film is soft, elastic, cold resistant, non-toxic, transparent, odorless, good adhesive and easy to process, so it is a kind of green film.

3.The films are divided into transparent, semi-transparent, mirror-faced, three-dimensional, frosted (coarse/fine) different kinds and different colors.

4.The three-dimensional film/sheet is bright-colored and beautiful, with strong stereoscopic impression, good hand-feeling, high grade.

5.PU film is a kind of top grade environmental products with extensive application.

Main Applications of Product

Hand bags, tablecloths, suitcases, shopping bags, articles for medical treatment and babies, cosmetic bag, ice bag etc.

|

Model(mm) SJLM-EVA/PU-Z |

1200 |

|

Screw Diameter(mm) |

125/multi-extruder co-extrusion |

|

L/D Ratio of Screw |

30:1 |

|

Width of Finished Film/Sheet (mm) |

1200 |

|

Thickness of Finished Film/Sheet (mm) |

0.15-0.80 |

|

Max. Extrusion Capacity (kg/h) |

250 |

|

Design Line Speed (m/min) |

20 |

|

Total Installed Power (kw) |

250 |

|

Overall Dimensions(L×W×H) (m) |

18×5×4.5 |

|

Weight (T) |

20 |

The above data shall be subject to change without prior notice.