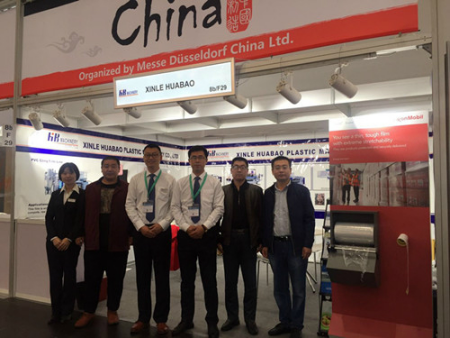

Xinle Huabao Watch: European market

The sales manager of Xinle Huabao Plastic Machinery Co. Ltd. Ma Shuchen to "Plastics News" said, K-show has been in the four consecutive.

As the plastic machinery exhibition of the world's largest and most influential exhibition, the world's best machinery manufacturing enterprises have participated in, advanced technology, technology and the future development direction is shown here, this is the first time to show their good works and learning opportunities, through to compete with the world elite industry project the company to make their own understanding of their own shortcomings and gaps, in order to have better development and improvement.

He added that the company has always been to direct promotion as the main sales channels, to promote the one-stop nanny service system, finding and solving problems, take one to one service, so the advantage of as much as possible to avoid some unnecessary link delays, and is actively looking for Europe strategic partners, strive to occupy a bigger market share in europe.

Casting equipment development today, faster and larger output, less energy consumption, more environmentally friendly is the development trend in this area, Europe has the advantage, after all, started early, science and technology strength is stronger, but in recent years, our company's products have been sold to Europe, which shows more and more equipment between the gap between us and Europe small, compared to our manufacturing costs lower, more affordable and a series of advantages, and they do not have, in the face of challenges, we are ready.

The company achieved annual sales revenue of 350 million yuan in 2015, as of now, is expected to exceed $400 million in 2016, the company showed a steady growth trend.

In recent years, with the increasing volume of business, export sales accounted for 50% of the company's total business, the main market in the Americas, the Middle East, Southeast Asia and other markets.

Our company has been the development of strategic industrial 4 concept and Chinese manufacturing 2025 included in the Future Ltd, it is to enhance the intelligent level of the manufacturing industry, accelerate industrial restructuring and upgrading in the US has been using the only way which must be passed, and preliminary exploration in device for remote monitoring, remote operation, remote diagnosis and so on, I believe the future will be fully in other ways the implementation of.

In 2016 the company launched the CPE casting unit newly developed equipment, has cutting, curing, high degree of automation online, the production of amorphous points and no tail, widely used in food, industrial packaging composite material.

When it comes to the next biggest challenge, he said: the enterprise, whether executives or bosses or employees, there will be some people see other people how to make money, there will be psychological impetuous, so I think the biggest challenge is their own, can do now, do a good job in practical research, each manufacturing. There is an old saying Rome was not built in a day, sinking heart to every step, every step of the way, go beautiful, talk about the poor country, hard work and prosperous, this is the biggest challenge.